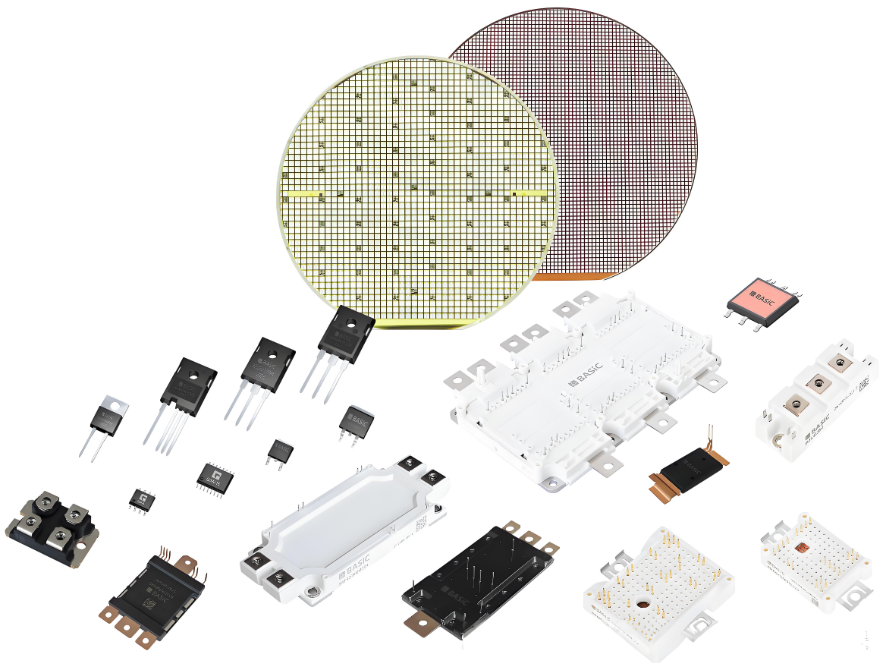

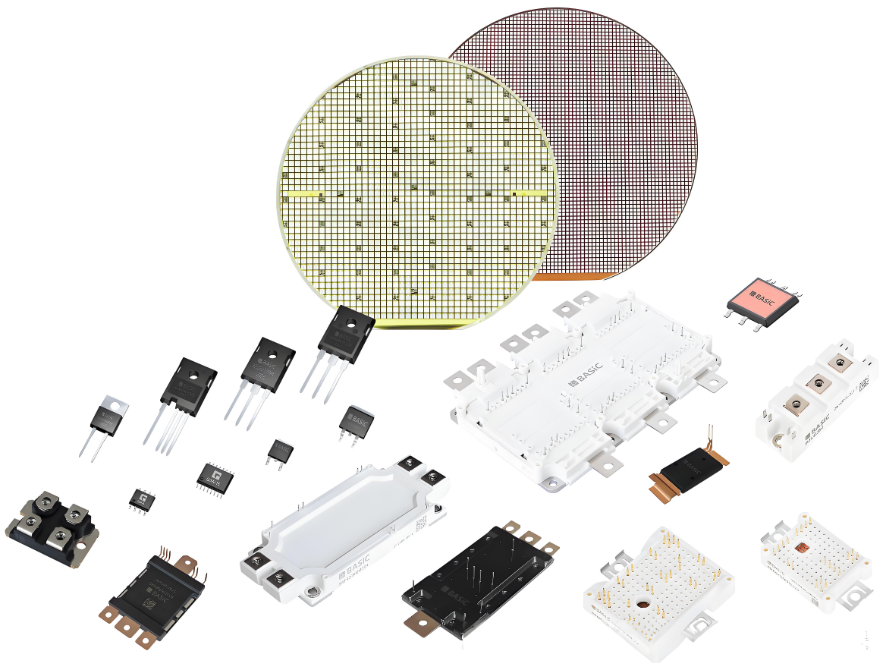

Silicon Carbide (SiC)

Silicon Carbide (SiC) is a wide-bandgap semiconductor material that has revolutionized power electronics, offering superior performance compared to traditional silicon (Si) in high-voltage, high-temperature, and high-frequency applications. Its unique physical properties make it a critical enabler for energy-efficient technologies across industries, driving advancements in renewable energy, electric vehicles (EVs), industrial automation, and telecommunications.

SiC’s exceptional characteristics stem from its crystalline structure and wide bandgap (approximately 3.26 eV, more than twice that of silicon), which deliver:

-

High Temperature Tolerance: SiC devices operate reliably at temperatures exceeding 300°C, eliminating the need for complex cooling systems in demanding environments like industrial motors and aerospace equipment.

-

High Voltage Capability: With a critical electric field strength 10 times higher than silicon, SiC supports higher breakdown voltages, enabling smaller, lighter power components for high-voltage applications (e.g., 600V to 10kV+).

-

Low Losses: SiC exhibits lower on-resistance and switching losses, translating to higher energy efficiency in power conversion systems. This reduces energy waste in applications such as solar inverters and EV chargers.

-

High Frequency Performance: SiC’s fast switching speeds allow for higher operating frequencies, minimizing the size of passive components (inductors, capacitors) and enabling more compact system designs.

SiC’s advantages make it indispensable in sectors requiring efficient power management and durability:

-

Electric Vehicles (EVs) and Hybrid EVs: SiC power modules in EV traction inverters, on-board chargers, and DC-DC converters reduce energy loss by up to 50% compared to silicon, extending driving range and enabling faster charging.

-

Renewable Energy: In solar inverters and wind turbine converters, SiC devices enhance efficiency (up to 99%), reducing the cost of energy production and supporting higher power density in smaller form factors.

-

Industrial Automation: SiC-based motor drives and power supplies improve efficiency in factory machinery, robotics, and HVAC systems, lowering operational costs and carbon footprints.

-

Grid Infrastructure: High-voltage SiC devices (e.g., MOSFETs, diodes) enable smarter, more compact grid-tied converters, energy storage systems, and HVDC (High-Voltage Direct Current) transmission, enhancing grid stability and renewable energy integration.

-

Aerospace and Defense: SiC’s ability to withstand extreme temperatures and radiation makes it ideal for power systems in aircraft, satellites, and military equipment, where reliability is critical.

The SiC market is rapidly expanding, driven by the global shift toward electrification and renewable energy. Key trends include:

-

Cost Reduction: Advances in wafer manufacturing (e.g., larger 8-inch wafers) and economies of scale are lowering SiC device costs, making it more competitive with silicon in mid-voltage applications.

-

Integration: SiC modules are increasingly integrated with gate drivers and sensors, simplifying system design and improving reliability.

-

Wide Adoption in EVs: Major automakers are adopting SiC in next-generation EV platforms, with forecasts predicting SiC penetration in over 50% of EVs by 2030.

Leading manufacturers in the SiC space include Infineon, STMicroelectronics, Wolfspeed, onsemi, and Rohm, each investing heavily in R&D to expand product portfolios and improve performance.

Silicon Carbide, SiC, wide-bandgap semiconductor, power electronics, electric vehicles, renewable energy, SiC MOSFET, energy efficiency, high-voltage semiconductors.